Pipeline Welding Inspection: Guarding Pipelines with Accuracy and Know-how

Pipeline Welding Inspection: Guarding Pipelines with Accuracy and Know-how

Blog Article

Advanced Methods in Pipeline Welding Examination: Developments and Technologies for Improved Accuracy and Dependability in Weld Assessment

The landscape of pipe welding assessment is undergoing a substantial improvement, driven by advanced techniques that assure to improve both precision and reliability in weld analyses. Technologies such as computerized inspection systems and advanced imaging technologies are redefining standard methods, while non-destructive screening approaches ensure product honesty is maintained.

Significance of Weld Inspection

Ensuring the integrity of pipe welds is important to the general safety and integrity of industrial systems. Welds offer as the structural foundation of pipelines, which transfer a range of liquids under differing pressures. Issues in welding can lead to disastrous failures, leading to not just considerable financial losses yet additionally possible ecological calamities and dangers to public security. For that reason, strenuous examination of welds is important to the lifecycle of pipe framework.

The relevance of weld evaluation prolongs beyond simple conformity with regulatory standards. It serves as a proactive measure to recognize and remedy flaws, such as incomplete combination, porosity, or splits, prior to they escalate right into major problems. Reliable evaluation strategies also add to the durability of pipes, minimizing upkeep expenses and enhancing operational efficiency.

Furthermore, thorough weld assessments foster trust fund amongst stakeholders, including regulative bodies, investors, and the areas served by these pipes. By making certain that all welds satisfy the required standards, organizations can minimize threats and support their online reputations. In recap, weld inspection is essential not just for operational stability however additionally for the broader effects it holds for safety and environmental stewardship.

Automated Examination Systems

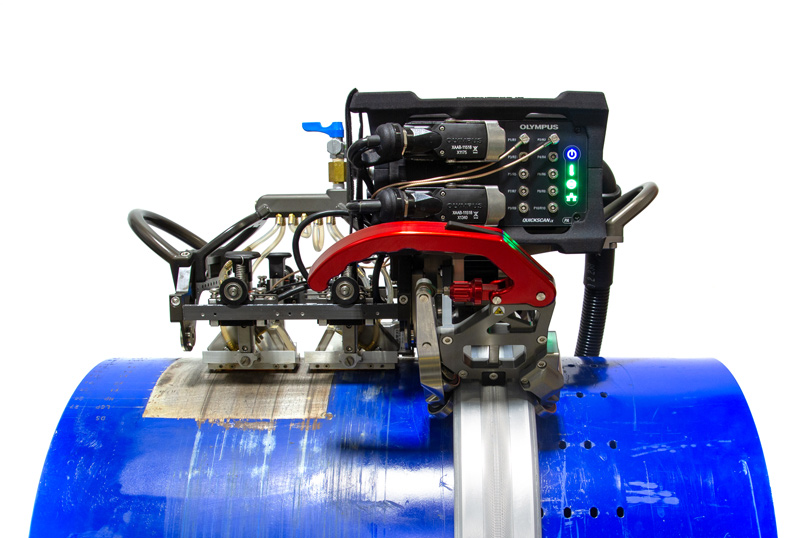

The assimilation of automatic inspection systems in pipeline welding has transformed the technique to making sure weld high quality and stability. These systems use innovative robotics and fabricated intelligence to carry out inspections that are not just quicker yet also more consistent than typical methods. Automated systems can cover considerable sizes of pipes efficiently, recording data that human assessors might ignore due to fatigue or environmental conditions.

Among the key advantages of computerized inspection systems is their capability to run in unsafe atmospheres, reducing the threat to human inspectors. They utilize various non-destructive testing (NDT) techniques, such as ultrasonic testing and magnetic particle evaluation, to analyze weld stability without compromising the structure. The information gathered is processed in real-time, enabling prompt responses and timely restorative actions when problems are determined.

Moreover, automated systems assist in the standardization of evaluation processes, making certain that each weld is evaluated against regular criteria. This not only improves the reliability of results but additionally enhances conformity with governing standards. As sectors remain to focus on safety and security and functional effectiveness, the function of automated assessment systems in pipe welding will definitely broaden, leading the way for more sophisticated high quality guarantee methods.

Advanced Imaging Technologies

Regularly utilized in modern-day pipeline welding assessments, progressed imaging innovations have substantially improved the capacity to discover and evaluate weld problems. Strategies such as digital radiography, calculated tomography, and thermographic imaging provide assessors with high-resolution photos that disclose sub-surface flaws and architectural disparities that might be invisible to the naked eye.

This leads to much faster assessments and improved accuracy in determining important flaws. Computed tomography, on the various other hand, offers three-dimensional imaging, allowing assessors to visualize complex geometries and analyze the integrity of welds from several angles.

Thermographic imaging uses infrared modern technology to detect variations in temperature, identifying locations of prospective weak point or tension within the weld. These innovative imaging innovations not only enhance defect detection prices but likewise minimize the moment and resources needed for pipeline assessments. Therefore, they play go to these guys a vital duty in preserving pipeline safety and reliability, ensuring conformity with market requirements while lessening functional threats.

Non-Destructive Checking Techniques

Utilizing different techniques, non-destructive testing (NDT) methods are crucial in pipeline welding examinations, enabling the examination of weld honesty without jeopardizing the product's architectural honesty. NDT encompasses a series of methods, including ultrasonic screening (UT), radiographic screening (RT), magnetic particle screening (MT), and color penetrant screening (PT) Each technique has unique benefits and applications relying on the specific needs of the examination.

Ultrasonic screening utilizes high-frequency audio waves to find inner imperfections, supplying exact dimensions of weld density and integrity. Pipeline Welding site Inspection. Radiographic screening utilizes X-rays or gamma rays to produce pictures of the weld, disclosing inner flaws that may not be visible externally. Magnetic bit testing works for finding surface and near-surface discontinuities in ferromagnetic materials, while color penetrant screening highlights surface area fractures by using a tinted color

Incorporating these NDT approaches right into pipe welding evaluations enhances the accuracy and reliability of weld evaluations, making sure that possible failings are recognized early. As markets require higher criteria for safety and efficiency, the role of NDT in preserving the integrity of bonded frameworks remains to be pivotal in pipe building and upkeep.

Future Trends in Weld Assessment

As we aim to the future of weld assessment, innovations in modern technology are poised to transform the approaches utilized for evaluating pipe honesty. The assimilation of synthetic intelligence (AI) and device discovering in examination procedures is expected to enhance the accuracy of defect detection and anticipating important source upkeep. These technologies enable real-time data analysis, making it possible for assessors to determine potential issues before they rise into substantial issues.

In addition, making use of drones equipped with sophisticated imaging systems is getting traction. These airborne examinations can cover huge locations quickly, recording high-resolution photos and information that can be assessed for problems in hard-to-reach places. This not only enhances safety and security however also raises efficiency in the inspection process.

Moreover, the advancement of wise sensing units installed in pipe systems provides the possibility for continuous surveillance. These sensors can discover adjustments in pressure, temperature level, and resonances, offering important insights into the health of the welds with time.

Conclusion

To conclude, the combination of advanced techniques in pipe welding examination substantially improves the precision and dependability of weld evaluations. Technologies such as computerized assessment systems, progressed imaging technologies, and non-destructive testing techniques play a crucial function in boosting flaw discovery prices and promoting aggressive maintenance approaches. As these innovations proceed to advance, they will certainly additionally guarantee the security and efficiency of pipe systems, inevitably contributing to the honesty of vital framework.

Report this page